Coating & Finishing

Blasting

- Enclosed blast cabinet with #10 glass bead fit, 20″ x 24″ x 32″ part

- Enclosed blast cabinet with sand, 21″ x 12″ x 32″ part

- Blast room with #10 glass bead for stainless steel only, door 12′ x 12′ and 24′ deep

- Blast room with sand for black steal, door 12′ x 12′ and 12′ deep

Polishing

- 2 Hammond buffer jacks with dual heads and adjustbale speed control with 4″ belts.

- Cincinnati dual head buffer jack with buffing wheels and compouns

- Hammond single jack with 6″ belt for stainless steel only

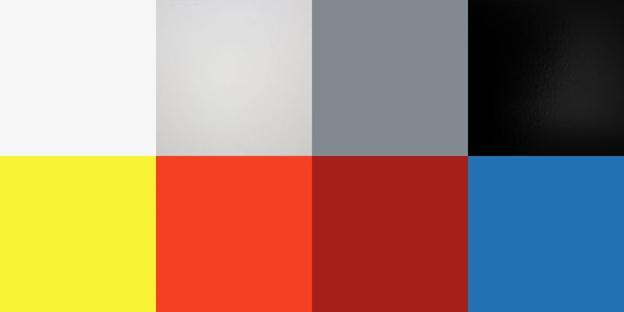

Several Stock Powder Coat Colors

Powder Coating

- Plaforization (degreasing and phosphate in one step)

- 6′ x 6′ x 12′ Batch Oven

- Gerref Industries wash system with timed heated cycles

- Several stock powders to choose from

- Change over several times a day

Deburring

- 18″ Chicago tub vibratory tumler with walnut shells for non-ferrous materials

- 48″ tub vibratory system

- 2 Wheelabrator Burrbench portable vibratory system with ceramic media for both stainless steel and black steel

Belt Sanding

- AIM 36″ wide, 5″ open

- Timesaver, 18″ wide 3″ open

- Burr King belt finisher, 6″ wide

Miscellaneous

- 2 Purewash Prop-Jet agitated parts, washer and degreaser

- 2 Lighting Cleaner acid polisher and weld cleaner

- 3 Dynafile II pneumatic files

- Dynawheel tire sander

- Dynafile inline sander

- 2″ x 18″ and 4″ x 18″ belt sanders

- 6 pneumatic DA sanders

- 6 bench grinders, 6″ wide

- Nickel Plating

- Hard Coat Anodizing

Get Started on your Project!

Get in touch with our team to get started on your next project and get a quote on any custom metal fabrication, manufacturing or engineering and design services.